Prägewerkzeuge & Präzisionsgravuren

Maßgeschneiderte Prägewerkzeuge und Präzisionsgravuren

ÜBER UNS

Renommierter Zulieferbetrieb für namhafte Firmen der Schreibgeräte, Kosmetik, Automobil und Verpackungsindustrie.

Wir fertigen hochwertige Prägewerkzeuge zur Veredelung Ihrer Produkte. Langjährige und motivierte Mitarbeiter gewährleisten höchste Qualität bei kurzen Lieferzeiten.

Spezialisten für Prägewerkzeuge & Präzisionsgravuren

Modernste CAD und CNC-Technik

Langfristige Kundenbeziehungen

Kurze Lieferzeiten

Über 40 Jahre Erfahrung

10 Mitarbeiter

Firmenstandort in der Metropolregion Nürnberg

LEISTUNGEN

PROFITIEREN SIE VON HOCHWERTIGEN PRÄGEWERKZEUGEN UND PRÄZISIONSGRAVUREN

WORTE DER GESCHÄFTSFÜHRUNG

Starke und langfristige Kundenbeziehungen.

„Der Erfolg unserer Firma basiert auf der Grundlage unserer langfristigen Kundenbeziehungen und unserer langjährigen und kompetenten Mitarbeiter.“

STEFAN KREMSER

GESCHÄFTSFÜHRER

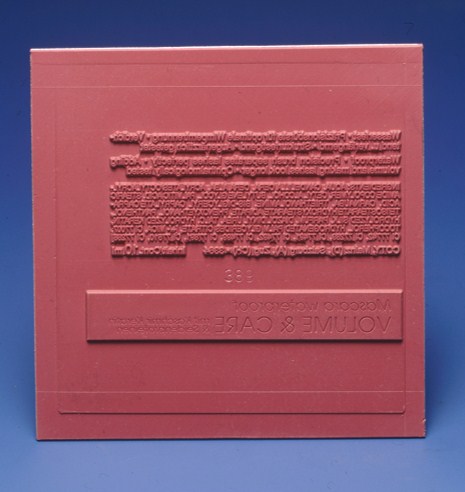

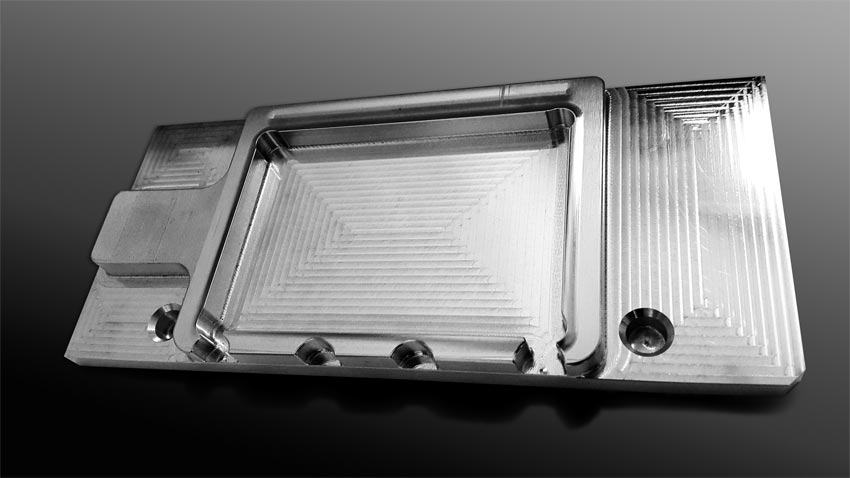

KUNDENPROJEKTE

Prägewerkzeuge & Präzisionsgravuren

Die Kremser GmbH steht Ihnen hier als kompetenter Partner zur Seite. Wir entwickeln und fertigen hochwertige, an Ihre Anforderungen angepasste Produkte.